First off, My intention here is to clear the waters some, and provide accurate information about what really good pancake dies can do, and why. This type of die was designed and invented to work on a very wide range of metal types and thicknesses, and when made properly, can cut extremely thin, soft metal; for as thin, (or thick), as almost any use a jewelry maker or metal artist might have.

(all dies shown -except the one in the first RT saw picture- are made by me)

Poppy design by Linda Weiss, cut in 24 ga. brass :

Kokopeli design by me, (one step) cut and embossed in 26 ga. copper :

Internal Sun Face – 20 ga. brass and copper :

Made of tool steel, and heat treated properly, they can cut many thousands (even many tens of thousands, or more) of parts of practically the most intricate shapes (one area of limitations is complex, multi-hole pierced designs) normally cut with a jeweler’s saw. I have been specializing in making these dies since 1987, and have developed my techniques to get the most out of the process in a production environment. I’ve had to encounter everything that could go wrong, and figure out everything to do to make things work right, and find out what is possible or not, what is practical or not.

Secondly, not all pancake dies are created equal. Some are made in ways that don’t facilitate the cutting of thin or soft metals well (if at all), or are not good for intricate designs, and/or don’t last very long. In my interaction with die customers over the years, there seems to be more and more people that only have exposure to the not-best dies, and less and less people who understand pancake dies in a fuller, more accurate way. That being in the context of them originally known to jewelers and metal artists as “RT Stamping Dies”, or RT Dies, made in certain ways, capable of certain things. It’s a fairly simple technique, in concept, but the best results require that many things have to be done with precision.

A selection of parts cut with ‘Pancake-Donut’ dies I’ve made for various people:

Above: one-step cut/emboss die and mold . Butterfly design by Timber Bay Home and Garden.

Below: 2″ by 1.5″ Pegasus for 18 ga. copper. 5/64″ steel, #4/0 blade.

———————————————————————————————————

The technique of making a blanking die from a single plate of steel, by cutting a flap into the steel, with the design at the end of the flap, has it’s roots in a technique known as The Continental Process. This was developed and used in the early-mid 20th century.

These were still 2-part dies, but without the hinge/flap ,but differ from conventional 2-part die sets in that both male and female parts of the die are created with a single pass of a saw blade through the die stock (plate).That concept was later refined and tweaked, my assumption being that the one-piece, flap/hinge aspect was added then, and presented to the jewelry making community by Roger Taylor of England as The RT Blanking System, and sold in the U.S. by Rio Grande Jewelry Supply. This link just below is for the original paper that Roger Taylor published in 1980.

https://silversmithblogdotcom.files.wordpress.com/2014/05/project-report-no-12e_1-the-r-t-blanking-system-may-1980.pdf (copy/paste works on that)

Versions of early R.T. saws :

Knew Concepts saw designed by Lee Marshall

Below: a saw that I use, which is a modified , motorized version of an original Bonny Doon Saw Guide

The RT material provides a wonderful introduction to the one-piece die concept and presents some creative ways of utilizing it in the design of pieces. However, it is not a complete instruction guide for start-to-finish hardened dies, and lacks important details. Using that product is how I got started in 1986, and I started Sheltech in 1987, making custom dies and punching out parts for local jewelry manufacturers, in the beginning. Rio Grande also produced a video about the RT Stamping System, which is probably floating around cyberspace, but that was discontinued along with the RT gear a number of years ago. I’m the person in the video, and I did technical consulting, but have since altered a few of the technique details, so that video in not entirely accurate as far as being a precise “how-to” . That, my friends, is a subject way too long for a short video, trying to cover too much ground at once.

Susan Kingsley’s book ‘Hydraulic Die Forming For Jewelers and Metalsmiths’ (1993 or later version) has a very good chapter, which I consulted on, that covers the basics of how to make your own pancake dies “the right way”. This is highly recommended for anyone interested in making their own dies.

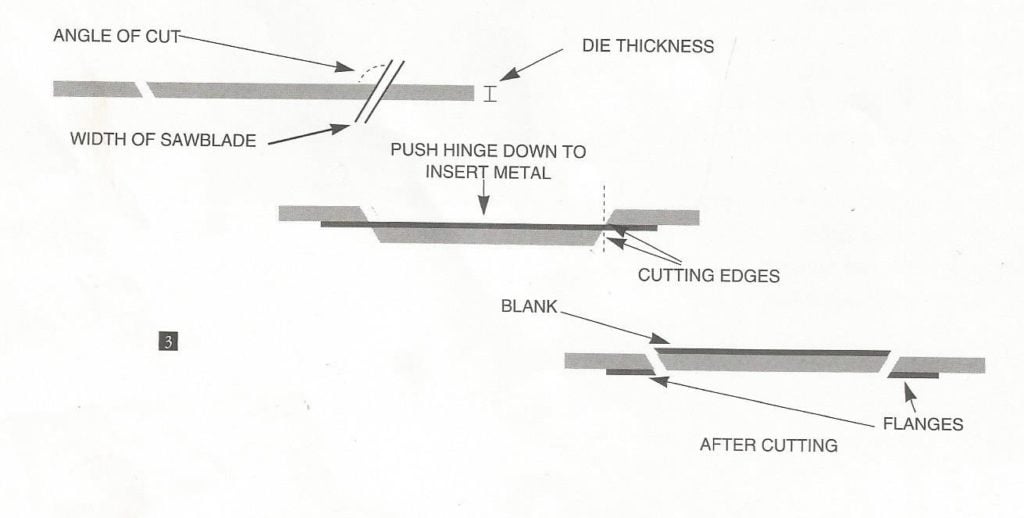

Above: diagram from SK’s book showing basic RT concept of angled cut through the die plate for creating male & female die components that have very tight tolerance, and also the directionality of how to load and press this type of die (the die can be flipped over in the press, with the male part moving downwards, but what’s important to see is which way the male (center) part opens up in relation to the female part (outer ‘sides’ in the diagram). Dies made this way only cut one way; if the die is opened the reverse way , and metal is loaded and pressed, it will only emboss the shape, not cut the part out.

This book is somewhat brief, regarding RT/pancake dies, compared to the Taylor paper, but it does cover some important things for making the best dies, such as heat treating, that are not in the RT paper. It shows what was a brilliant tool, the old Bonny Doon Saw Guide, which has been replaced by Knew Concepts saws. The (very nice) Rio Screw press is discontinued, and now hydraulic presses and accessories are offered by Bonny Doon, through Rio Grande, and Potter USA . As soon as I started experimenting with this process, I encountered some significant gaps in the information base that was provided with the RT kit, and this was the genesis of my obsession with refining and perfecting it. That, along with necessity -the mother of invention- which came in the form of a continual stream of people wanting good dies, many of whose projects forced me to push the limits of what had been done with this process.

5″ Sun Face die, my design , shown without it’s solid (plastic steel & Lexan) conforming mold/base. Samples cut in 26 ga. copper .

Below: Snowflake design by Paul Crabtree of Colorburst Studios.

The left die is a normal pancake die. The right one is for the set of center holes and is at the extreme limit of what is possible with this process.

Above: close -up of the (one-step) TBHG butterfly

They (Lisa M. Fida) have run many, many thousands of these in

soft 30 ga. copper.

—————————————————————————————–

Below: a selection of small, intricate parts cut from normal pancake dies (non-donut)

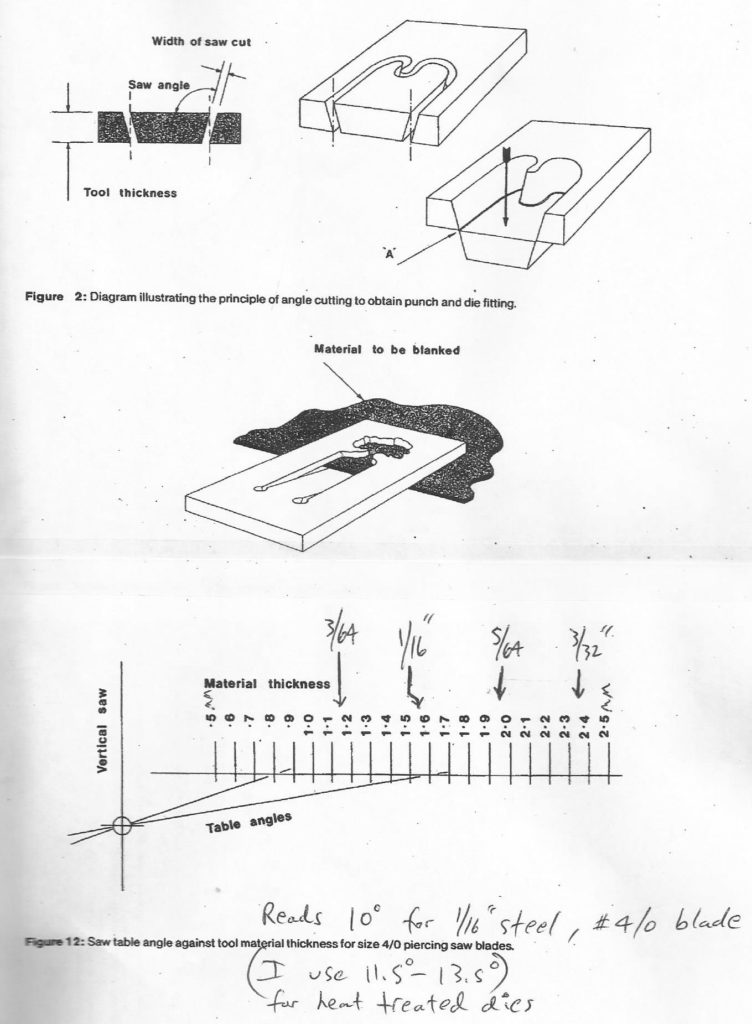

The most important attribute of these dies is that when cutting the design (with the saw reciprocating vertically) the steel plate is tilted at a specific angle so that the tolerance between the male and female components of the die becomes tight. This happens because the tilt compensates for the width of the gap left by the saw blade. This one aspect is incredibly important, and at the core of the entire “RT” concept. It’s like a pair of new scissors that’s nice and tight at the joint, cuts very cleanly, and works on thin material, whereas a loose pair will have problems, and may not even cut. That’s because material squeezes in between the scissor halves, because the joint is loose and sloppy, and leaves room for the material to go into. If the tolerance is tight, there’s nowhere for the material to go, except to get cut.

Below: page from the original R.T. paper, showing the basic concept of creating positive and negative die parts with one saw cut , leaving very tight tolerance between them. Noteworthy is my handwritten note about the angle used for a 4/0 blade cutting 1/16″ tool steel. It shows the difference between the “theory” of what angles to use, and what angles actually work best with heat treated dies. I do what might be thought of as extreme die making, because my angles can be past the limit of what is advisable for anyone without some experience doing this .

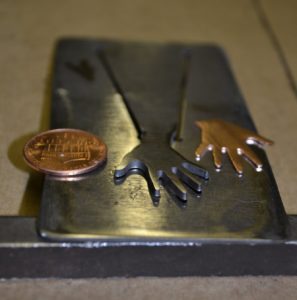

Below: small hand die , of 1/16″ steel, cut with size 4/0 “Platinum” blades. Sample cut in 24 ga. copper

Below : the same die, right after sawing , opened the reverse way to show the tapered cross section of the fingers due to the sawing angle .

The gist of all this is that any pancake die cut with no tilt starts out just like loose scissors because the cut that makes the flap is perpendicular to the steel plate. The importance of using the correct angle becomes more obvious when cutting thin or soft metals , and certain alloys and tempers that have more resistance to shearing. It has been my “job” -as well as an honor and privilege- to make and use tools for so many great people over the years . It has also been imperative to get the dies to perform as well as possible and, if made correctly , they can be incredibly productive. If not, they can be next to useless in some situations where a well made die would shine.

Even when attempting to make pancake dies the correct way, it’s easy to make them just a little bit loose, and have the same sort of problems as described (and encountered by many of you). Well made dies (even heat-treated tool steel ones) can loosen up with extended use, and also start to have problems. So, in my not-actually-humble opinion, it’s (generally) extremely important to start out very close to what is as tight as possible, so that a die can cut parts cleanly for as long as possible, and in many situations, it is essential. What steel is used is also very important. Inexpensive dies are made of inexpensive steel, which is not fully hardenable, so pointy or delicate areas will fail much sooner that they would on heat treated tool steel die, and many small, complex kinds of designs should not even be attempted unless tool steel is used and properly heat treated. I make almost all of my dies out of 0-1 oil-hardening precision ground flat stock, which has the best overall characteristics for this process. With the right machine, a Wire EDM, pre-hardened flat stock can be used, but those are expensive to buy or get work done on, and not the scope of this piece. For dies bigger than the sizes of pieces used in jewelry (6″ by 8″) for example) it would be better to scale up the thickness (to 3/16″ perhaps) but there are drawbacks to this, such as cost, difficulty of making, and weight. I had one die made to cut and shape a 9″ leaf in 26 ga. copper; the die was 24″ by 12″by 3/16″) and was, needless to say, physically hard to use. The only other “improvements” were/are doing more with the process than just cutting flat parts without holes, which I have developed methods for.

——————————————————————————————

MY Videos :

Fundamentals of Using Pancake Dies

Pancake-Donut Blanking Dies:

Pancake Die Mutations- One Step Cut and Emboss

Pancake Die Demo 1

Sheltech Show and Tell – Various Parts…

Manual and Motorized Die Saws That I Use

Here’s a nice video put out by Rio Grande, featuring Jayne Redman. The animated cross section of the angled-cut die is especially effective at showing what the two old diagrams above are all about. Some technical details don’t align perfectly with mine ; the big one would be that, for absolute best results in maintaining a correct sawing angle, you don’t rely on freehand sawing. Hence, the BD saw guides I use, the Knew Concepts saws, and, oh yeah, from the man who started all this, the RT saw. A device which holds the saw/blade in perfect orientation to the tilted saw table. Given that the variations in angle I use to make a specific die a little tighter or looser are about 2 degrees, freehand sawing just doesn’t cut the mustard if you’re operating close to the limit of tightness. I seriously doubt anyone can consistently saw within 2 degrees . This means that one is extremely likely to overshoot and undershoot the perfect angle without a saw-holding device .

Web:

http://sheltech.net/

Email :

sheltech@yahoo.com

darshelton@hotmail.com

Now on FB :

https://www.facebook.com/Sheltech-1186953114672908/

https://www.facebook.com/profile.php?id=100011659549448

David “Dar” Shelton – March 2018

{ 8 comments }

sheltech

Latest posts by sheltech (see all)

- A Brief History of the RT/Pancake Die Universe - March 10, 2018

- The Timber Bay Embossed Butterfly - April 4, 2015

- Amazonite and Silver Set - August 8, 2014