Jewelry making is constantly changing. Whether you’re using findings or soldering and casting, how you create jewelry has many options. So, what is metalsmithing? Seems like a simple question, right?

Funny how you’d think you know everything about metalsmithing since it is basic information for most, how much we enjoyed reading about it. Even at this point!

For example, we love just plain simple information always at wikipedia. We could spend hours looking terms up.

So, not surprsing we enjoyed reading this on wikipedia: MetalSmithing

“

“

The English word smith is cognate with the somewhat archaic word, “smite”, which means “to hit” or “to strike”. Originally, smiths were craftsmen who shaped or formed metal with hammer blows. However, the old etymological guess of “smite” as the source of “smith” is without foundation. The wordsmith derives from an old Teutonic word, smeithan, to forge. The root is seen in the Greek word σμίλη, a burin.[1]

As an English suffix, -smith connotes a meaning of specialized craftsmen — for example, wordsmith and tunesmith are nouns synonymous with writer orsongwriter, respectively.”

But we also found a great page about MetalSmithing at our friends site at Jewelry Making Daily.

“We define metalsmithing as “creating jewelry through the manipulation of various metals.” Those manipulations or metalsmithing techniques include fabricating metal jewelry by forming and shaping it with hammers, mandrels, and other tools, sawing with a jeweler’s saw or cutting with metal snips, doming with a metal dapping set, forging, fold forming, drilling holes for design elements or for use with cold connections such as rivets and screws, soldering, texturing metal with hammers and other metalsmithing tools, and metal stamping.”

What is nice about the Jewelry Making Daily page is it has additional information such as shaping.

”

Metal Shaping: The elasticity of silver is exploited through a range of techniques that use stakes, formers, and hammers to produce three-dimensional forms for jewelry. Compared with basic metal forming methods, there is more scope and freedom in metal shaping. It is essential for metal to be soft and malleable when shaping and it should be annealed regularly. Metal shaping techniques include:

- Dapping (also known as doming) involves creating a hollow dome from a disc or other shape by shallow forming using a dapping/doming block or die and a doming/dapping punch. Blocks or dies are available as cubes or rectangular blocks made from steel or brass and consist of semicircular polished concave domes graduating in size. Punches are made of steel or hard wood and are cylindrical with one flat end for striking with a hammer and a rounded ball at the opposite end. They are available in sets with each rounded ball measuring a different diameter and fitting a matching concave dome on the block.

- Swaging: A swage block is a steel former with parallel grooves or channels, which, when used with the appropriate former, can create curves, troughs, and tube from flat sheet.

- Fold forming utilizes the properties of metal to create lightweight, strong, solder free, and flexible pieces. A bench vise, mallet, raising hammer, and stake are all that is required. Each piece starts with a fold that is shut in a bench vise and then tapped closed with a mallet on a steel block or pushed through the rolling mill. There are many variations for continuing from here, including opening the piece and planishing along the fold line to confirm it, or keeping the fold closed and forging with a raising or creasing hammer by striking the metal at right angles to the fold, causing the piece to curve as the metal becomes thinner. Regular annealing is essential. Once a sufficient curve has been achieved, the piece is annealed and opened.

- Forging refers to the controlled shaping of metal using the force of a hammer and utilizes the ability of silver to stretch and elongate. It is used for spreading metal, tapering, curving, and creating wedges. The type of hammer and stake or support used will directly affect the outcome-a cylindrical hammer, such as a raising or creasing hammer, will displace the metal at right angles to its curve pushing the metal along the axis; a domed headed hammer, such as a blocking or ball-pein hammer, will displace the metal all round. A flat stake is the most popular to work against and will not usually affect the results; a curved or rounded stake will cause the metal to spread outward.

- Raising is used by silversmiths to create hollowware from a single sheet of metal without a solder seam and can be used on a small scale for creating both symmetrical and asymmetrical hollow forms for jewelry.”

So the next time someone asks you…. What is MetalSmithing? O.K., maybe there IS just a little bit more than a simple explanation. But at least you can narrow it down to a low-descriptive limited paragraph. 🙂

Back to the workbench.

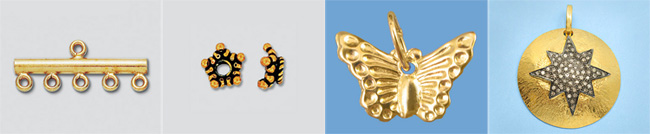

CGM Findings

Latest posts by CGM Findings (see all)

- Interesting Rocks and Minerals - September 19, 2016

- What Makes Rocks so Interesting? - September 19, 2016

- Helpful Tips for The Tucson Gem Show - January 20, 2015

CGM Findings

Latest posts by CGM Findings (see all)

- Interesting Rocks and Minerals - September 19, 2016

- What Makes Rocks so Interesting? - September 19, 2016

- Helpful Tips for The Tucson Gem Show - January 20, 2015