LEE EPPERSON

Fire scale has been the scourge of sterling silver casters since the first silver was poured into a mold. It has been a thorn in the side of silver fabricators. Fortunately there are ways to prevent fire scale while silver soldering.

This paper describes a simple, inexpensive method of preventing fire scale during vacuum casting.

Fire scale is cuprous oxide, the combination of copper in the silver or gold with oxygen. Fire scale forms whenever silver or gold containing copper is heated above 1000 degrees F. Unlike cupric oxide, the black coating on silver, fire scale cannot be removed in the pickle pot. Normally it is removed by abrasion, electro striping or left as a surface finish.

Fire scale usually shows up, as a purple or copper stain in the metal, during the polishing process. It prevents sterling silver or gold from being polished to its fine, brilliant luster.

The method of preventing fire scale during the casting process consists of preventing oxygen from reaching the metal while it is cooled in the investment mold. The use of a reducing flame and graphite crucible during the melting process will help in keeping oxygen from the metal as it is melted. Oxygen must be removed during the cooling process in order to prevent fire scale.

By accident I found a way to prevent fire scale during vacuum casting. I can now produce sculptures in sterling without worrying about how to get rid of fire scale. It is my impression that fire scale forms as long as the sterling is above around 1000 degrees.

Fire scale is forming as long as the sprue button is red. Therefore fire scale is forming during most of the time the metal sits in the mold before

quenching

This is a sample of a regular sterling silver casting that was cooled in the reducing atmosphere created by the process described in this paper.

The casting was quenched seven minutes after the pour. It was brushed with a brass brush to remove the investment. Investment can still be seen under the bear. The casting was not pickled and does not need to be pickled before polishing it. It is free of both cupric oxide, the black oxide, and cuprous oxide, fire scale.

The method described in this paper to prevent the forming of fire scale during the cooling process is very simple. It allows the metal to cool in a reducing atmosphere.

Castings, when removed from the mold, are bright silver. They do not have to be pickled to remove the black coat. In some instances they can be polish with jewelers rouge after removal from the quench water.

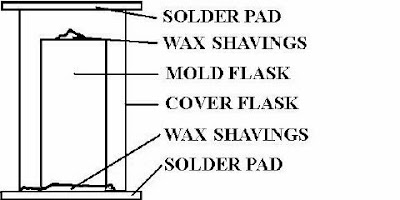

The process requires two smooth soldering pads, scrap wax shavings and an empty flask the next size larger than the mold flask.

I place some wax shavings on a solder pad before I start the pouring. Once the metal is poured I place the mold flask on the wax covered solder pad.

I then place the larger flash around the mold flask.

Wax is then thrown on the sprue button and the second solder pad is immediately placed on top of the cover flask.

The wax inside the cover flask absorbs the oxygen as it attempts to burn.

The flask should be cooled for a longer period of time then normal as the heat does not dissipate as rapidly because of the cover flask.

When the flask is first quenched the wax forms seals with the investment and prevents it from breaking up. The flask has to be removed from the water and the surface of the investment scrape to remove the wax/investment skin. The flask is then quenched as normal.

FIRESCALE PREVENTION

STEP ONE

Place about a tablespoon of wax shavings on a solder pad prior to pouring the metal.

STEP TWO

Place the hot mold flask on the wax shavings on the solder pad. The wax will immediately melt and seal the bottom of the flask to the solder pad, which prevents air from entering the investment mold and metal from the bottom side.

STEP THREE

Place the cover flask around the mold flask. The wax will seal the cover flask to the solder pad.

STEP FOUR

Throw wax shavings on the sprue button.

STEP FIVE

Place a soldering pad on the cover flask. The wax shavings will attempt to burn and will absorb all the oxygen around the mold flask and the metal it contains. A reducing atmosphere will be created around the mold flask. There will be no oxygen remaining in the cover flask to combine with the copper in the sterling silver to form firescale.

STEP SIX

Quench the flask in cold water. The cooling water will cause the scrap wax to form a bond with the investment when it hits the water. The flask should be quenched for a few seconds then removed from the water. A sharp tool should be used to break open the investment on both ends. The quenching cycle should then be continued.

The cooling of the casting flask will take longer due to the fact it is enclosed in the cover flask. The cooling time before quench should be increased by a minute for small castings to several minutes for larger castings.

leessilver

Latest posts by leessilver (see all)

- CASTING PAPER UNDER CONSTRUCTION - October 30, 2010

- CASTING PAPER UNDER CONSTRUCTION - October 30, 2010

- PAPER NO 4 CREATING LARGE JUMP RINGS - October 15, 2010

You must log in to post a comment.