If you are missing blowpipe

February 14, 2010

The information bellow is of experimental nature. No testing as far as safety of modification, has been done. Use you own judgement whether or not it is something you want to experiment with. The information provided “AS IS AND WITHOUT ANY WARRANTY WHATSOEVER”.

Whenever there is a discussion about torches, somehow it is always on how quickly it can melt a ton of gold, and is it hotter than the sun. For my money, I want a flame just barely hot enough to melt solder; I want my torch to be as light and as small as possible; and I want to be able to adjust flame to different operational envelopes. In short, I am missing blowpipe. But, I am not missing blowing into it. Is it possible to eat proverbial cake without ever buying one?

I have been using Little Torch for many years. It is not perfect, but it was as close to my requirements, as I could manage. Still, even adjusted to produce reducing flame, the torch is a bit harsh. I have been modifying tips trying to improve operational characteristics with some degree of success. However, the type of flame that blowpipe can produce, had remained elusive, until recently.

Why blowpipe flame is different ?

Chemists differentiate two types of flame – premixed and diffusion. Premixed type of flame is exactly what the name says – fuel an oxygen were premixed prior to burning. All torches produce premixed type of flame. An example of diffusion type is the flame resulted from burning candle. In diffusion burning, oxygen is separate from fuel prior to burning, and when burning starts, oxygen diffuses though fuel. Such flame is irregular, with different temperature zones, but from jeweler’s point of view, diffusion flame is very desirable.

Another characteristic of flame is the flow of burning gases. If we adjust oxygen just right, we could observe a highly organized blue cone, surrounded by yellow envelope, and transparent outer shell. The reason that we could observe this arrangement, is because torches designed to produce laminar flow of premixed gases. The flame produced by blowpipe is very much different. It has no obvious structure, because the flow of gases is turbulent. In real life, any flame will be a combination of both types of flow, and flames would differ only in percentages of each component.

Design

All right, that was helpful. Once I understand the nature of flame, I know how to design torch tip. What needs to be realized from the very start that it would be impossible to imitate blowpipe flame completely. But, it should be possible to reduce temperature of the flame and increase the size of reducing zone. Turbulence of the flow will also be enhanced.

To reduce temperature of the flame, some oxygen must be replaced with air, and to increase the size of reducing zone, flame diameter must be increased. My theory is that it should be possible to adjust a torch so there is only enough oxygen to combine with 80% of available propane. Remaining 20% should combine with surrounding air and burn with much cooler flame reminiscent of blowpipe. It is also possible to achieve with regular torch, but commercial tip design makes it very difficult. That makes perfect sense, because designer was striving for maximum efficiency, which is to ensure complete burning of propane with almost any knob setting. My design goal is quite different.

Implementation

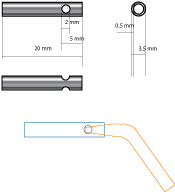

I started by taking one of the tips with sapphire nozzle and cutting of sapphire end. Next step was to make copper tube out of copper sheet. Take a look at the drawing bellow.

Copper tube length – 20 mm; outside diameter – 3.5 mm inside diameter – 2.5 mm; side openings – 2 mm; the distance from the opening end to the tube end is 5 mm.

Copper tube length – 20 mm; outside diameter – 3.5 mm inside diameter – 2.5 mm; side openings – 2 mm; the distance from the opening end to the tube end is 5 mm.

Few words about side openings. They are there to supply air to be diffused into propane/oxygen mixture. For them to function properly – inside diameter, tip diameter, distance from the end, size of openings – everything must be in particular relationship to each other.

Giving formulas to calculate these variables would be a waste of time. What is needed is a practical approach. I have chosen 2.5 millimeter inside diameter, because it is more than double of original diameter. By increasing diameter, I am increasing zone of low efficiency, which makes task of finding required knob setting easier. The distance, where side openings should be, is determined by inserting torch end and marking where the tube touches the tip. Distance from tip end to the mark is the required distance. Drill two small holes with 0.5 mm drill, insert tip inside the tube and open propane. When propane is lit, there should be some evidence of air mixed in. If propane burns like with the regular tip, the openings are too small. Increase them slightly and try again. Increase only a little at a time. If you make them too big, propane would be going out all the time. Discard the tube and start all over again.

When satisfied with propane flow, add a little of oxygen and the flame should form. This tip requires less oxygen to operate than regular tip. The flame is cooler and that is exactly what I want. After all dimensions are finalized, the tube is soldered to the tip.

Pictures bellow show torch with modified tip and how flame should look when side openings are of correct size.

Study the picture of the flame above. At the very root, we see 2 white spots. These are the streams of air from each opening forming sub-zones. These spots are transitioning into 2 turquoise-blue zones, which a bit further, unite into single orange-yellow zone. The envelope around this yellow zone is the most valuable part of the flame, because it has the softness of blowpipe. The color tells the story. Instead of turquoise blue, we have violet blue of propane/air mixture burning.

Leonid Surpin

www.studioarete.com

leonidsurpin

Latest posts by leonidsurpin (see all)

- Introduction to CAD - May 26, 2011

- Influence of Poison on Silverware Design - March 6, 2010

- Eternity Ring DVD Guide - March 1, 2010

{ 5 comments… read them below or add one }

I am afraid, I do not think so. While mixture of propane and air can give a usable flame, acetelyne is another matter. In another words, it would require much higher concentration of acetelyne and much smaller openings. Very difficult to manage. That is better be left to experts.

Is it possible to use the modification when using acetelyne instead of propane?

Hi Leonid

I still mostly use a mouth blown torch and recently purchased a new one from Fischer Germany (the UK ones are not as good as they were) and my students generally like it as well – Propane and my mouth gives great control. I do have larger torches for melting and large jobs.

Regards

Thanks Leonid, great blog.

I have been using a blowpipe for a few years, but it is much less practical than just clicking on the Little Torch. It is nice to find a way to balance out these two torch designs. I am going to try this tomorrow.

Boy, I wish I had the tiniest fraction of this gentleman’s obvious mastery of the nebulous world of flame management. I’m still hoping I don’t blow my face off every time I turn on my little torch…