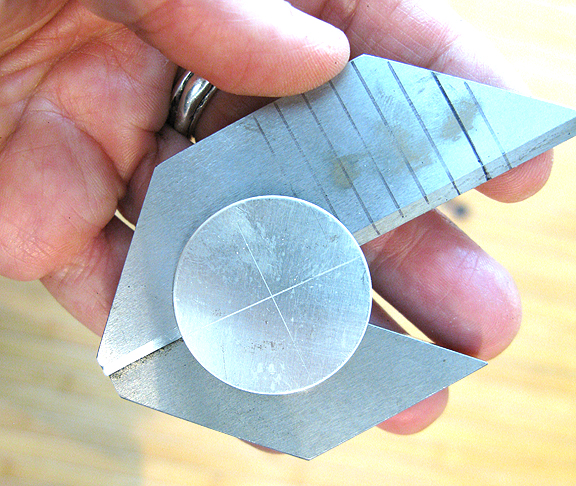

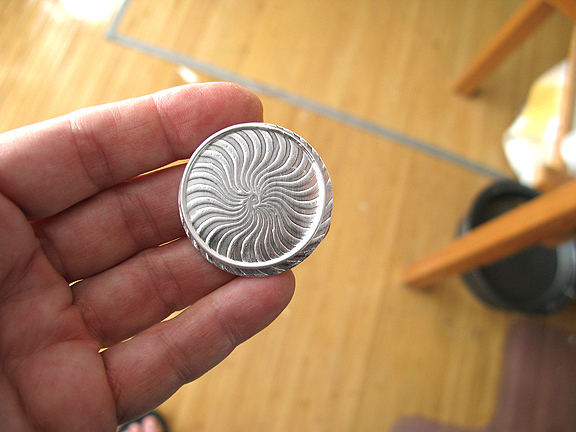

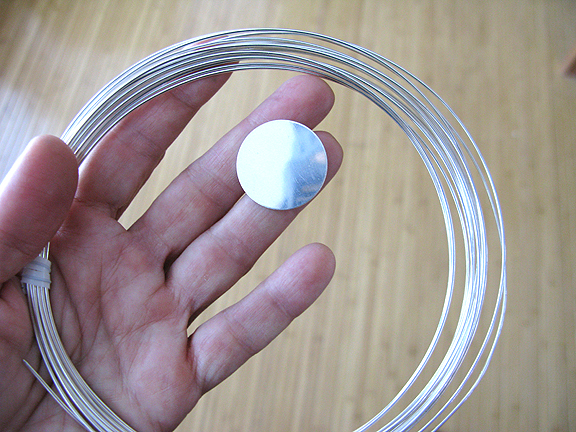

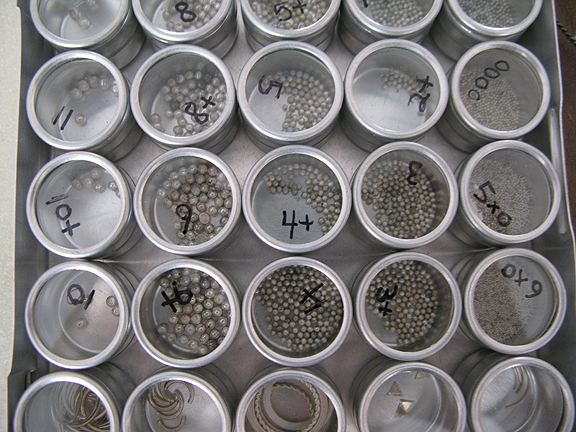

I’ve returned to the bench after a hiatus, and need to sharpen my skills in granulation. As I love English history, and all things Game of Thrones, I will make a simplified Anglo Saxon Disk pendant.I start with a fine silver disk, size 1 and 1/8 inch, or about 29 mm. The thickness of my silver disk is 24 ga, which is what I have on hand. The project would be to be 22 ga. or 20 ga, which would be less inclined to melt, but I am in the mood to make it work. |

The Anglo Saxon disk: Granulation on Silver

Basse Taille and Cloisonne Pendant: Part IV

Basse Taille and Cloisonne Pendant – Part III

Basse Taille and Cloisonne Pendant:Part2

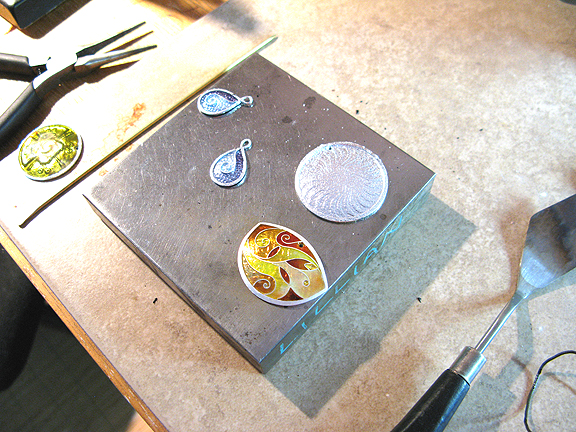

| Continuing from the last post, I am now going to use the etched plate to create and fine silver base for the enamel. I could use a rolling mill, but that would distort the image.

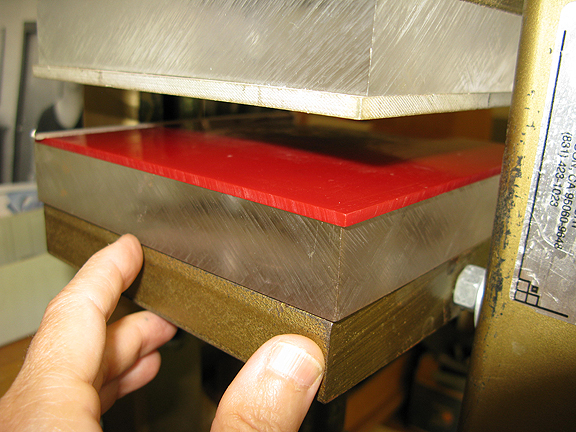

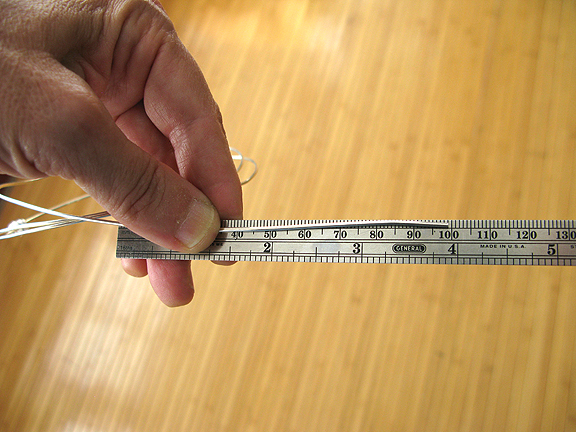

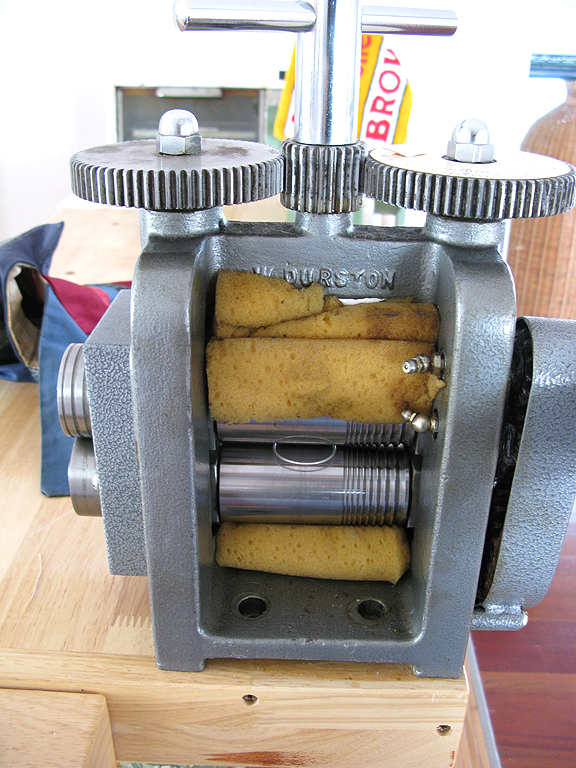

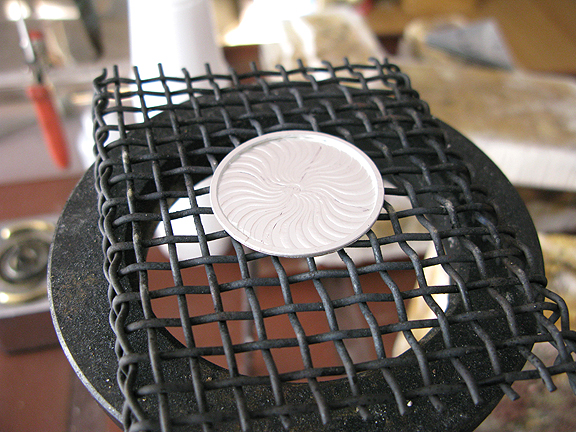

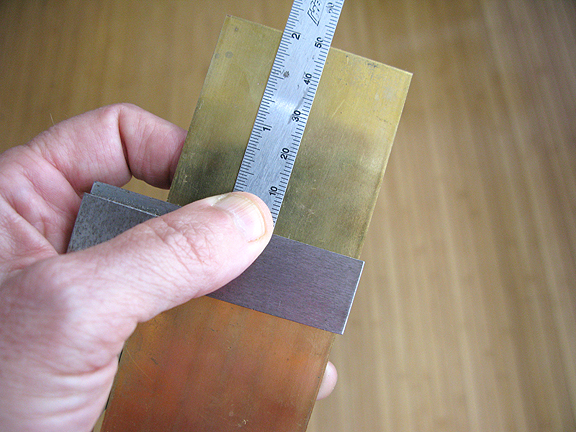

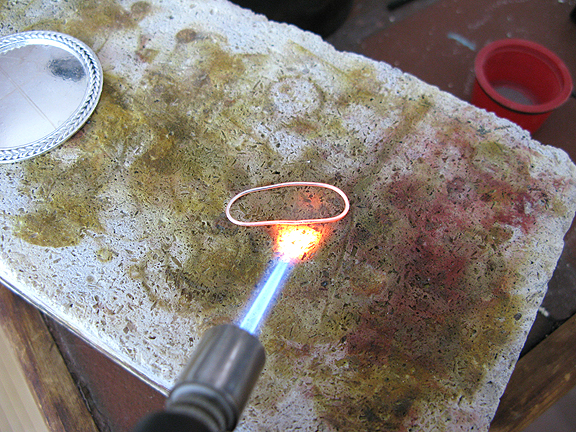

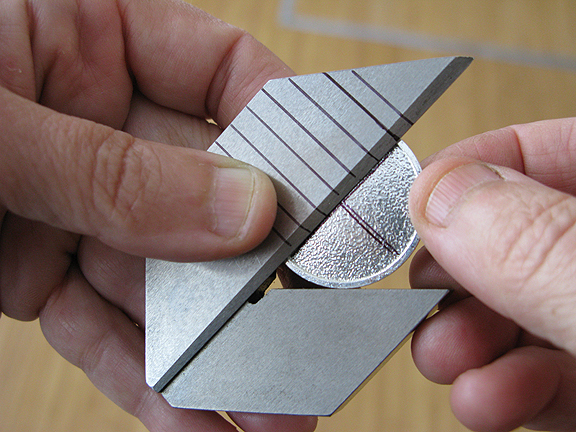

So I will use the hydraulic press instead, which applies pressure directly down and will not stretch the silver. I’ve carefully marked both the silver and the plate, and taped the urethane to the edge of the lexan block, so it folds straight down and doesn’t shift the silver when I close it. You can’t use anything to secure the silver to the brass because it will be printed into the piece. I put the silver, brass plate, urethane rubber pad and two lexan blocks in the hydraulic press, and jack that sucker up. And it looks OK. (Whew!) I only used about 4000 psi, I could anneal and go again, but I’d never get the silver exactly back into the right place, not worth the risk. Now for the rim, I do some math and measure out some 16 ga. fine silver wire. All the silver must be pure silver, never sterling, because I am going to fuse it all together. This means melt it together without solder, which is the best way if you plan to enamel it. Pure silver has a much higher melting temperature than sterling, and any speck of sterling, or solder would burn a hole in the piece when brought up to fusing temps. Make a nice neat joint, and spring the two ends of the silver together. Somehow, this makes it fuse better. I use butane and a Very Clean firebrick for fusing. I learned from my friend Iris, the mistress of fusing. You can see her at www.sandkuhler.com OK, so it doesn’t look that clean, but there is no flux or old solder there. Make it round on my favorite mandrel. And note that it is too small. But, I am going to flatten it in my mill, so I needed to allow for the stretching that will happen. Here I carefully roll the circle, changing directions to keep it roundish. I use Bluefuse as a fusing aid for the final fusing. It is a solution of copper salts that cause the silver to melt a little sooner where it is applied. It is the same technique used with granulation See here for more on that. And here I set it up on a tripod. This fusing must be done in total darkness, or you will melt it. This is the secret to granulation and all fusing. Darkness. I achieve this during the daytime with the aid of a tuna can. At night, I just turn off the lights. There it is, nice and shiny and fused together. The fused shine will hold up under the enamel, whereas a polish will not. And I keep it in white vinegar until I am ready to use it. I don’t have any reason for this, other than it works, and I am superstitious. |

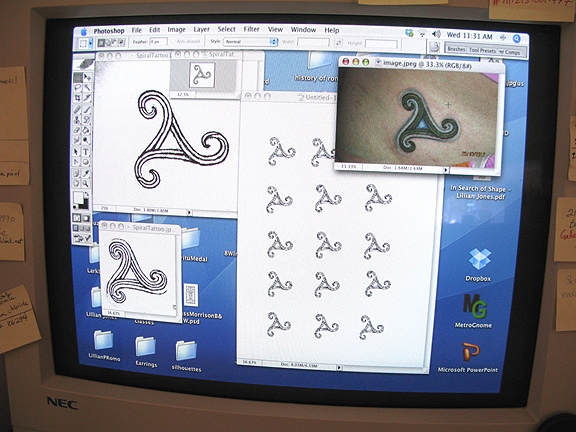

Basse Taille and Cloisonne: Making a Triskele Pendant, part 1

|

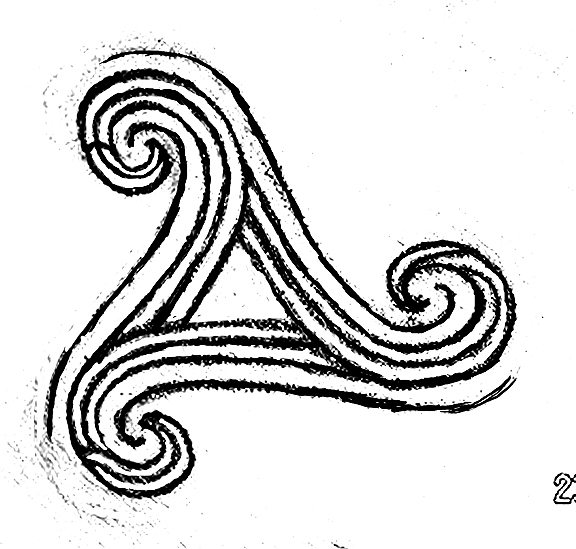

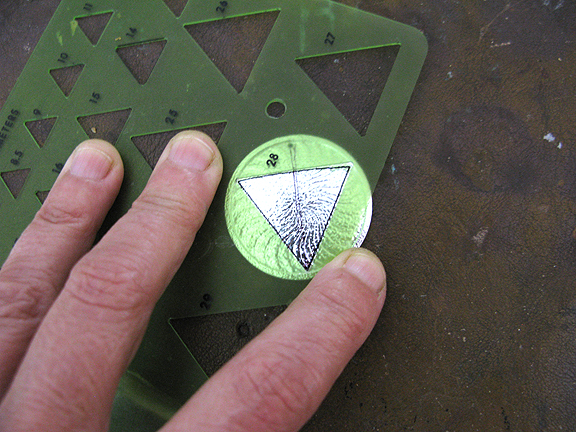

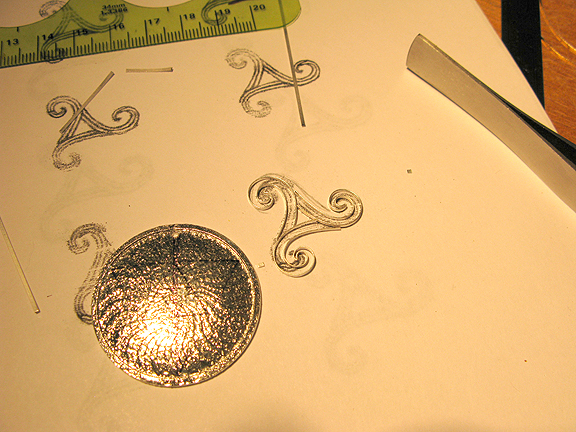

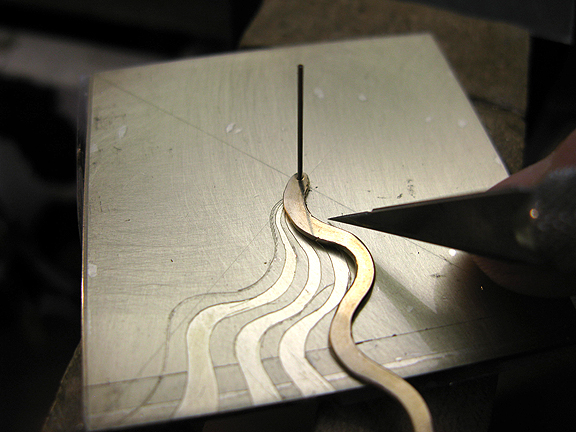

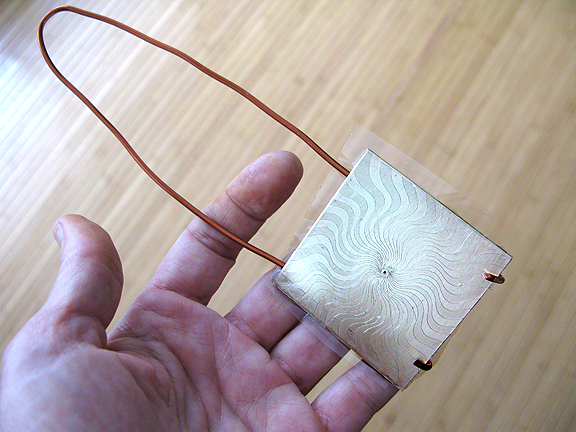

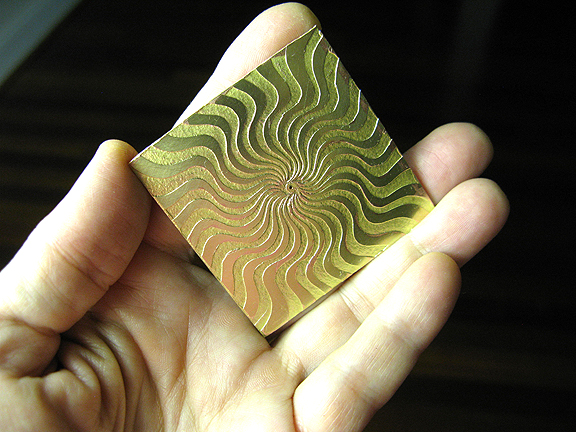

I want to make a triskele pendant, and have lately been interested in the surface that is under the enamel. For my first step I am going to create a new texture plate for this particular design. I’ll start with some heavy brass sheet. This is about 14 gauge, and I’ll cut a square that is 2 x 2 inches.

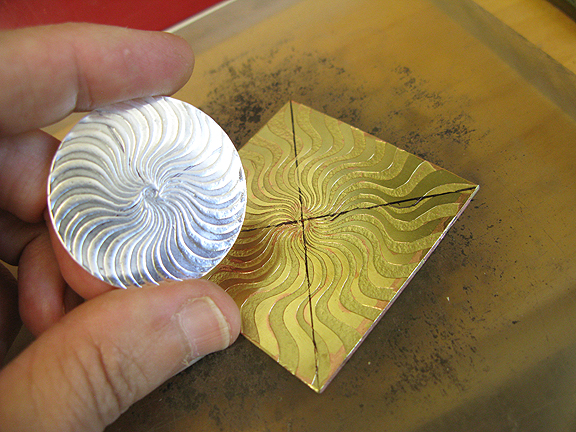

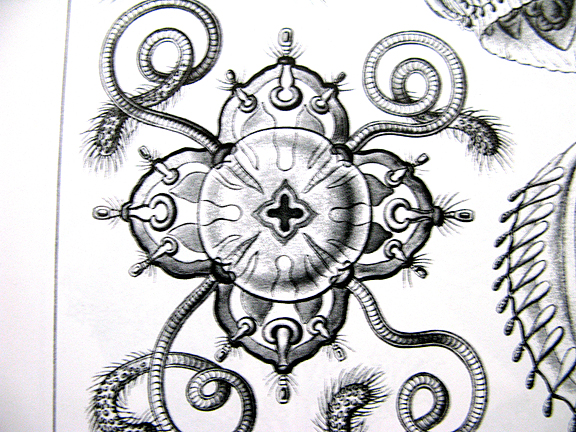

I had a cool idea about how to get the kind of image I wanted, so for this I find the center, tap a dent and drill a little hole. Next I forge a curvy wire and drill another little hole with the same size bit. Using the drill bit as a pin, I am able to rotate the curve all around the sheet. It is a little squirrelly but looks interesting. Since I need to etch the brass, I first cover it with clear packing tape, and then I cut the lines using a sharp blade and the brass wire as a guide. It looks larger in these images than it is, and this was painstaking. Here it is with all the tape cut and peeled away. I’ll electro-etch away the surface of the exposed brass.I like the way the hand drawn curves multiply, both mathematical and natural at the same time. Below I’ve taped some coated copper wire to the back of the piece, and I hope to establish a connection Here is my etching rig: a salt water bath with a copper anode and a motorcycle battery. It is pretty simple and not as messy as ferric chloride, but a lot more fiddly. So far I have not shocked myself with it. So here is the final plate. I’ll be interested to see how it prints the silver, which will be the next chapter of this project. I like it. It reminds me of these.

|

Torch Enameling: Cloisonne on Silver Part II

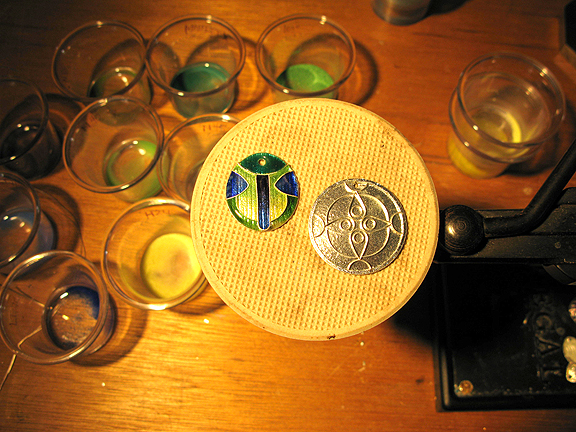

| This is the last part of a tutorial on torch enameled cloisonne.

In this picture I have picked a color pallet of green and blue and yellow.

And here I’ve filled the cells.

Firing with mapp gas, and a cheap little torch tip from Lowes.

And there it is, filled with enamel.

I have stoned the enamel down with a diamond hone.

Adding some decorative elements, as it is a rather plain design.

And finished, all done with a torch.

I made this for a friend who is always lost. It reminds me of this granulation piece I made as a class sample.

|

Torch Enameling: Cloisonne on Silver

| I had a great visit with Patricia White of Grains of Glass, the coolest enamelist’s website out there, and she mentioned that the current trend in enamel is ‘torch firing’. I enamel on silver, and torch firing is super easy and cheap, and can look great. I use propane and butane for this, either of which can be purchased at the local hardware store from less than $20.

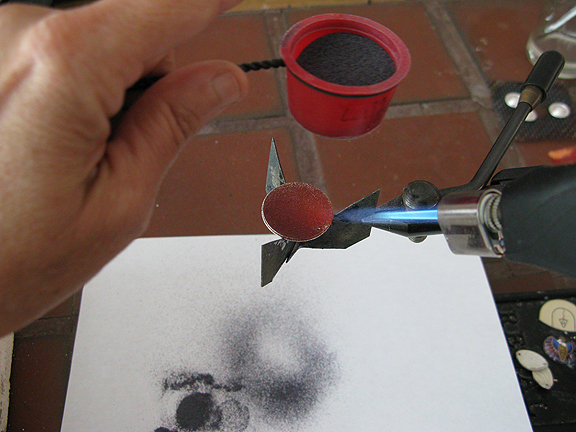

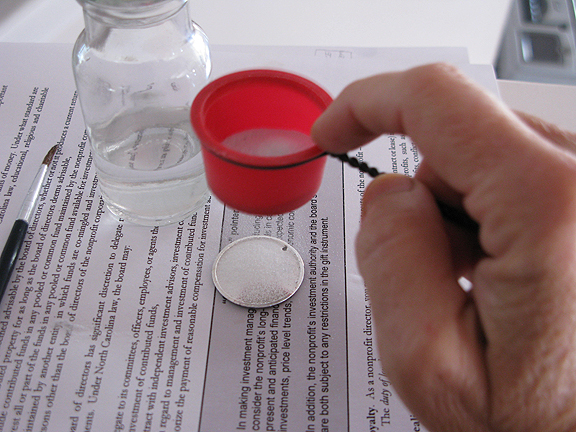

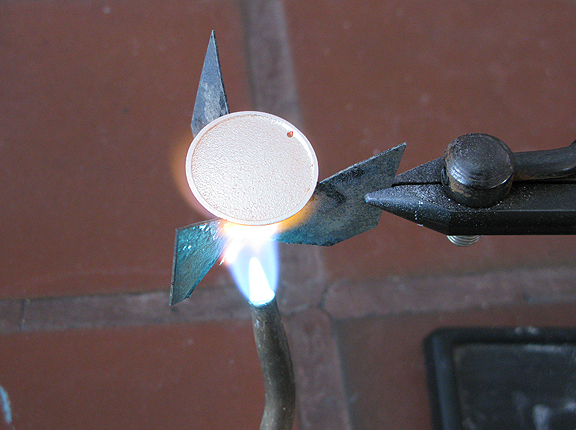

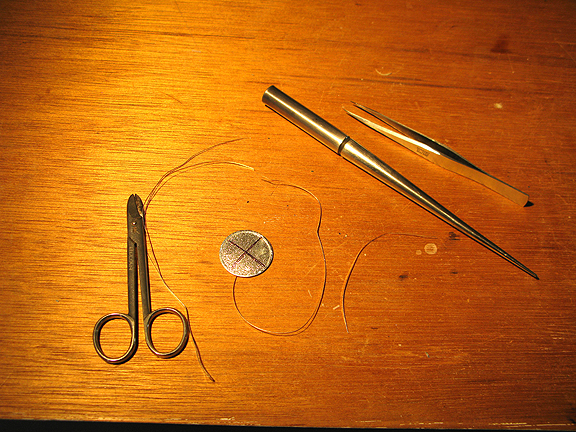

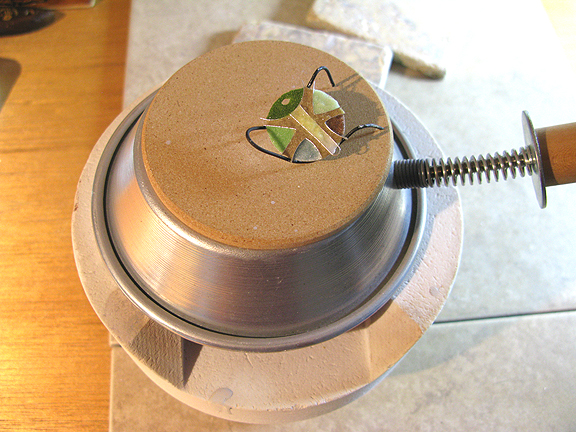

So I decided to make a tutorial. Turns out it’s really easy to get the bright beautiful cloisonne on silver that I usually get with my kiln, except the back is black, which is not really a sacrifice. So here goes. I start with FINE silver, a disk and some round wire. Sterling doesn’t work. I am going to fuse a rim onto the disk, so I start by measuring the disk. And cutting a length of wire a little less than the final circumference. I plan to hammer it into a flat washer, which will make it bigger. Using butane, I fuse the wire. Solder will not work. Round it into a ring, And flatten it into a washer. Or whatever shape: I am using a circle for an example.

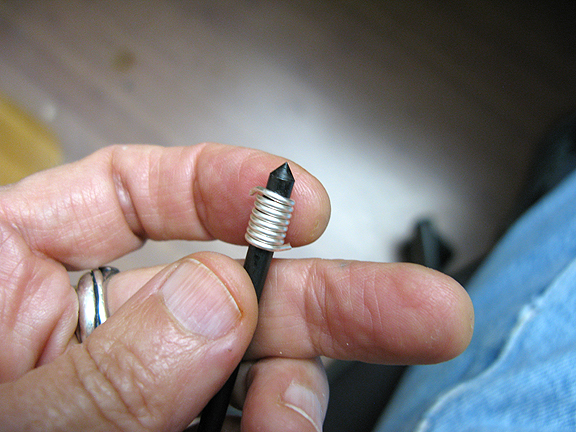

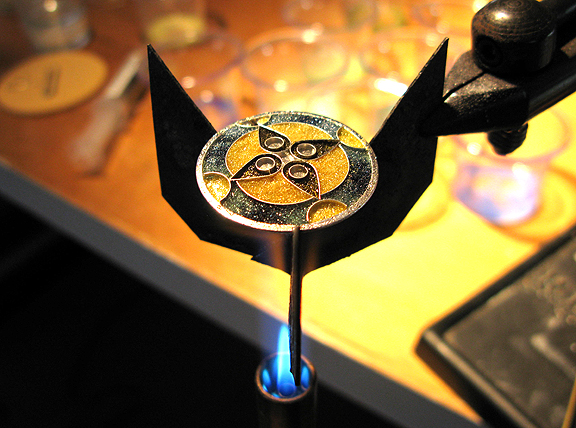

I like to heat it from below, using propane or air/acetylene. This is the same technique as granulation, only using wire instead of little balls.

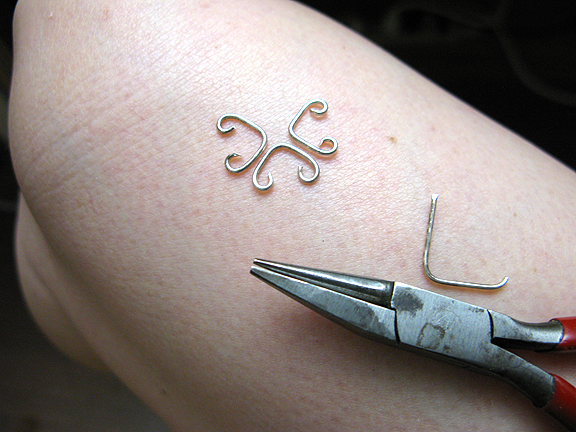

It also makes the silver nice and shiny for the enamel. Sometimes this is called ‘flash-fusing’, and the shine holds up under intense heat. Punch a hole for a jumpring or bail, Dome it slightly, And I am ready to put enamel on it. First I’ll apply the counter enamel, with the torch above the piece. If you heat it from below, you will lose your nice shine. Here I am using a little butane torch for a heat source. I am using Ndidi’s suggestion of Thompson’s Grisaille Black enamel. Now I apply a clear enamel to the front, using rubbing alcohol instead of water or Klyr-fire. It seems to burn off cleaner, and leaves a clearer coat of enamel. Heat it from below until it melts. Here I’ve switched to a hotter torch (actylene, but a big butane might work, propane does work) Now I begin the wire work by marking my axis with a sharpie. And make the wire design. This is going to be fairly simple. Place the shaped wires with Thompson’s holding agent (I hate Klyr-fire) and heat it until it glows. The wires will be stuck on, and ready for color. I’ll show the enameling in my next post, here. |

In Search of Shape

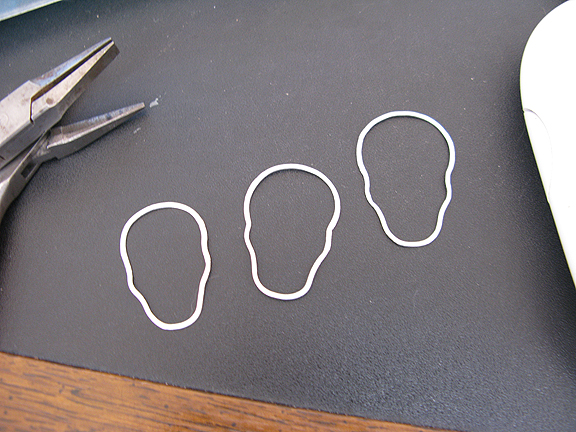

| My work for the last few years has all been circular. Not that there is anything wrong with that…

But my friends Marina, Addison and Bill advised me to look at some other options. So, after seeing a great brooch Bill welded, I decided on this: Kinda goth, but might be interesting made in prissy pretty enamel. So, I started with the outline. One idea is to abstract the shape, and the other is more literal. And fill in with some wire linework, to hold the color. Filling with enamel and firing. I love my new color palette strategy, it really works great.

I am not sure which shape I like best. Macabre is always classic. By the way, I have started to compile my notes from the blog on granulation in a more readable form here, if this is something you are interested in. |

Granulation with the Ultralite Kiln

| I am an enamelist, primarily. As offshoots of this passion I have also played with Jean Stark’s wonderful series of fused link chains, and lately, granulation.

These endeavors have in common the act of fusing fine silver. If it is chain, you are making circles to become links. If it is enamel, I am making fused borders (and soon, settings for small gypsy-set brilliants) and if it is granulation, I am just indulging my curiosity. Last Christmas I was granulating on a little butane burner, and made lots of earrings. (see previous posts) Reflecting on the matter, I resolved to try the little ultralite enameling kiln that I use for my enamels.

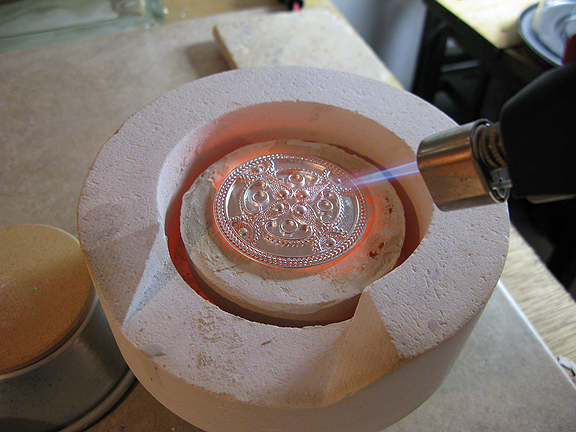

It is about 1500 degrees, and with a little butane torch on top, I should be able to get it to the eutectic threshold, which I am guessing is 1640 degrees, or the melting point of sterling silver. So beginning with a 2 inch disk, I use cable, wire and bosses to make a design, and some granules, too. Granules are the least fun aspect of granulation, so I try to find alternatives.

I use Bluefuse to attach the elements and heat it in the Ultralite kiln, and use a butane torch from above to bring up the temperature enough to fuse. It took several tries, but worked.

Now nex

|

To Capture Color