Why is it that every important thing has to be done on an urgent schedule? This interesting project started some 40 years ago.

Back then I was studying Karate and had the hobby of creating copper embossed western pictures.

I discovered I could pour wax into the back of the pictures and then have the wax cast into western buckles.

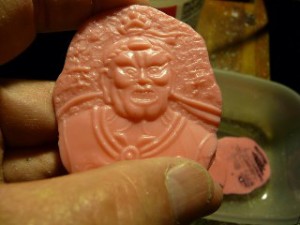

Along with the western pictures I created a Japanese Temple Guard picture.

Front side Back side

After 4 years of study two friends and I were promoted to Black Belts. I was looking for something to give to my fellow Black Belts in commemoration of our promotion. Then I remembered the Japanese Temple Guard copper picture I had created. The upper portion of the picture would make a great buckle for presentation.

I made a modeling clay frame around the upper portion of the Guard picture and poured in wax. Perfect. I now had a wax model.

It was obvious I needed an easy way to reproduce the buckle.

Back in those days I didn’t know what I was doing. Of course that statement implies I now know what I am doing. That statement may be a little stretch of the true.

I knew absolutely nothing about rubber molds. I didn’t have a wax pot. I made a one sided mold of my wax out of some cheap cold rubber material. I would melt wax in a tuna fish can and pour it into the mold. Unfortunately I had no way to control the thickness of the poured wax. Once the wax cooled I would scrape the back of the wax until it was the thickness I needed. Fortunately I only needed three buckles.

I eventually bought a wax pot and the learned how to make hot rubber molds.

That brings us up to March 4. There will be a special Black Belt promotion on the end of March. I need seven buckles for this special promotion. I have a problem. I long ago gave my original silver buckle to one of my instructors. The only item of the original buckle I have is the old one sided mold.

Here is where it gets interesting. Friday, March 13, I am having knee surgery. The Doctor says I should be back on my feet in several days. The plan is to cast seven buckles before the knee surgery then solder the findings on after I recover from the knee surgery.

So its back to pouring pink buckles wax into the old mold which is now falling apart. Unfortunately the mold surface has deteriorated slightly so that the surface is slightly rough.

The mold edge is torn on both ends.

At least I can squirt pink buckle wax from my wax pot into the mold. The pink wax is all that I have available.

I get seven waxes but they are of various thicknesses.

Scraping the wax away to make them thinner is way too time consuming.

How about putting the wax into a container of ice cubes and cold water. Once the wax is cold I might be able to grind the wax away.

How about that? It works. I grind the unwanted wax away with a large metal cutting burr then scrape the wax smooth with the edge of a pallet knife.

I put a clear plastic sheet over the burr to prevent wax from sailing all over the place.

Not the fastest way to create items but it will have to do.

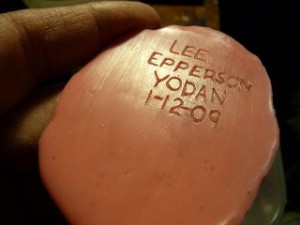

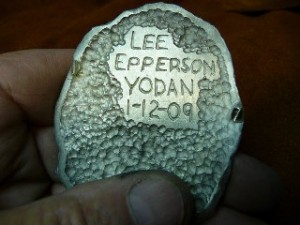

Once the back is smoothed I hand cut the names, promotion level and date into the back of each buckle.

I poured metal on March 11. Unlike most projects where a failure of one casting does not spoil the other projects the failure of one of these seven buckles will spoil the whole project. If one fails then it would be inappropriate to give out six buckles leaving one promoted individual without a buckle.

I clean up the buckles on Mar 12. Some times the casting angels are on the side of us artists. All seven buckles seem to be fine. A little touch up here and there and I should have seven Black Belt Buckles.

Note the finish of the sterling buckle. The finish is not produced by polishing but by my anti fire scale vacuum casting technique. (See Orchid’s tips from the Jewelers bench for details of the technique) The silver buckle was hand brushed with a brass brush to remove the investment.

Now it’s on to my knee surgery tomorrow morning Mar 13. I will grind sprues and solder on the findings after I recover from my knee surgery.

leessilver

Latest posts by leessilver (see all)

- CASTING PAPER UNDER CONSTRUCTION - October 30, 2010

- CASTING PAPER UNDER CONSTRUCTION - October 30, 2010

- PAPER NO 4 CREATING LARGE JUMP RINGS - October 15, 2010

You must log in to post a comment.