As we approach the end of 2021, I want to take a moment today to share the joy and gratitude I feel looking back on what Metalwerx has accomplished this year.

Through the unknowns and challenges we have all encountered during the pandemic, the creativity, passion, and resilience of Metalwerx teachers, staff, and students have guided us. Thanks to all of you, Metalwerx has grown in vibrant, exciting new ways. I am so proud of our team and grateful to you for helping us as we continue to celebrate learning, teaching, and sharing metal arts.

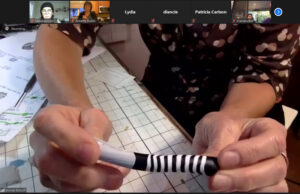

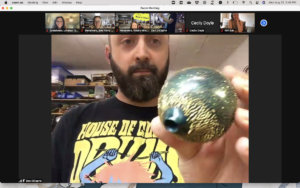

This year we officially committed to offering virtual classes and events in addition to our regular in-person programming. The resounding support and enthusiasm for this decision from our community has blown us away!

By bringing the wonderful world of Metalwerx learning online, there are ripples of additional benefits to our impact and our mission.

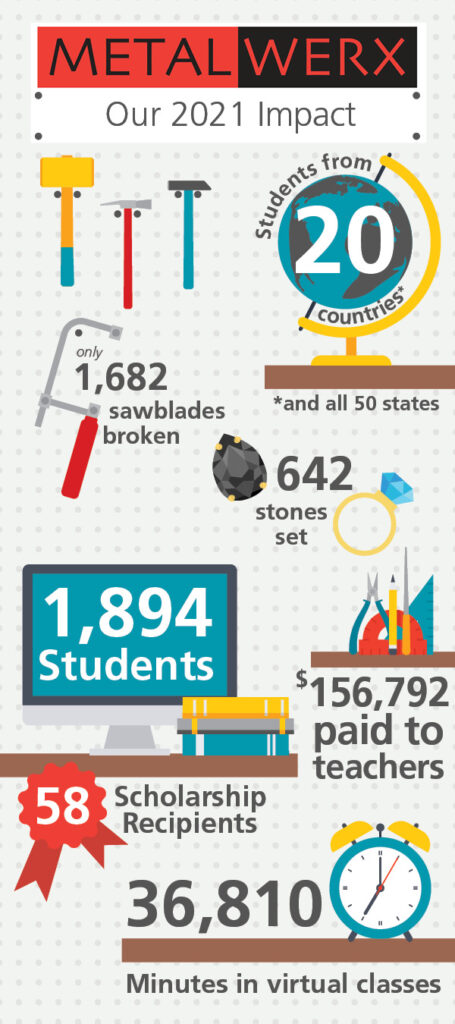

Thanks to YOU, this is what we accomplished this year:

We all started this year in the continuing unknown of a global pandemic. Yet thanks to YOU, Metalwerx is ending the year at an exciting moment of growth.

We now know that with your support, we can reach and inspire more teachers, artists, and students. With your support, Metalwerx can increase access to the metal arts, serving everyone from our local community to isolated areas of our country and even stretching around the world. Your support will increase our ability to offer more inclusive programming, help diversify and grow our teaching staff, share new voices and perspectives from BIPOC artists, and provide more scholarships.

Help us continue this exciting moment of growth in 2022! A donation to our annual fund will go directly to supporting our virtual and in-person classes and programs, furthering our mission to promote the education and advancement of metal arts personal and professional growth.

Click here to make a donation

Please consider making a donation of any size today and support this wonderful community of fellow makers, artists, teachers, students, professionals, and people! We can’t wait to see what you can help us do next!

{ 0 comments }

Latest posts by Metalwerx (see all)

- You helped make this year amazing! - November 29, 2021

- Announcing our Commitment to Continue In-Person AND Virtual Classes! - September 22, 2021

- Big Plans for Shopping Small for the Holidays - November 24, 2020